Hensley Home Check, LLC

24 Vesta Sue Court

Jonesborough TN 37659-5704

Inspector: Michael Hensley

State of Tennessee #1378

Property Inspection Report

| Client(s): | Mr. and Mrs. Homeowner |

| Property address: | Anytown, USA |

| Inspection date: | Friday, September 01, 2017 |

This report published on Sunday, November 26, 2017 5:51:21 PM EST

How to Read this Report

This report is organized by the property's functional areas. Within each functional area, descriptive information is listed first and is shown in bold type. Items of concern follow descriptive information.

Concerns are shown and sorted according to these types:| Safety | Poses a safety hazard | |

| Repair/Replace | Recommend repairing or replacing | |

| Repair/Maintain | Recommend repair and/or maintenance | |

| Minor Defect | Correction likely involves only a minor expense | |

| Maintain | Recommend ongoing maintenance | |

| Evaluate | Recommend evaluation by a specialist | |

| Comment | For your information |

Click here for a glossary of building construction terms.Contact your inspector If there are terms that you do not understand, or visit the glossary of construction terms at http://www.reporthost.com/glossary.asp

Table of Contents

General InformationGrounds

Exterior and Foundation

Basement

Roof

Attic and Roof Structure

Garage or Carport

Electric

Plumbing / Fuel Systems

Water Heater

Heating, Ventilation and Air Condition (HVAC)

Kitchen

Bathrooms, Laundry and Sinks

Interior, Doors and Windows

Wood Destroying Organism Findings

View summary

General Information

Report number: 0163

Time started: 9:45am

Time finished: 2:00pm

Weather conditions during inspection: Rain, Sunny

Temperature during inspection: Warm, 74

Inspection fee: 650

Payment method: Invoiced

Buildings inspected: One house

Number of residential units inspected: 1

Age of main building: 5

Source for main building age: Municipal records or property listing

Front of building faces: Southeast

Main entrance faces: Southeast

Occupied: Yes

Grounds

Limitations: Unless specifically included in the inspection, the following items and any related equipment, controls, electric systems and/or plumbing systems are excluded from this inspection: detached buildings or structures; fences and gates; retaining walls; underground drainage systems, catch basins or concealed sump pumps; swimming pools and related safety equipment, spas, hot tubs or saunas; whether deck, balcony and/or stair membranes are watertight; trees, landscaping, properties of soil, soil stability, erosion and erosion control; ponds, water features, irrigation or yard sprinkler systems; sport courts, playground, recreation or leisure equipment; areas below the exterior structures with less than 3 feet of vertical clearance; invisible fencing; sea walls, docks and boathouses; retractable awnings. Any comments made regarding these items are as a courtesy only.

Site profile: Minor slope, Moderate slope

Condition of driveway: Appeared serviceable

Driveway material: Asphalt, Poured in place concrete

Condition of sidewalks and/or patios: Appeared serviceable

Sidewalk material: Poured in place concrete

Condition of deck, patio and/or porch covers: Appeared serviceable

Deck, patio, porch cover material and type: Open, Covered (Refer to Roof section)

Condition of decks, porches and/or balconies: Appeared serviceable

Deck, porch and/or balcony material: Wood, Plastic fiber

Condition of stairs, handrails and guardrails: Appeared serviceable, Required repairs, replacement and/or evaluation (see comments below)

Exterior stair material: Wood, Metal

1)

Photo 1-1 |

Photo 1-2 |

2)

Photo 2-1 |

Photo 2-2 |

3)

Photo 3-1 |

4)

Photo 4-1 |

Photo 4-2 |

5)

Photo 5-1 |

Photo 5-2 |

Exterior and Foundation

Limitations: The inspector performs a visual inspection of accessible components or systems at the exterior. Items excluded from this inspection include below-grade foundation walls and footings; foundations, exterior surfaces or components obscured by vegetation, stored items or debris; wall structures obscured by coverings such as siding or trim. Some items such as siding, trim, soffits, vents and windows are often high off the ground, and may be viewed using binoculars from the ground or from a ladder. This may limit a full evaluation. Regarding foundations, some amount of cracking is normal in concrete slabs and foundation walls due to shrinkage and drying. Note that the inspector does not determine the adequacy of seismic reinforcement.

Wall inspection method: Viewed from ground

Condition of wall exterior covering: Appeared serviceable

Apparent wall structure: Wood frame

Wall covering: Cement fiber, Stone or faux stone veneer

Condition of foundation and footings: Appeared serviceable

Apparent foundation type: Finished basement

Foundation/stem wall material: Poured in place concrete

Footing material (under foundation stem wall): Not determined (inaccessible or obscured)

6)

http://www.reporthost.com/?CAULK

Photo 6-1 |

Basement

Limitations: Structural components such as joists and beams, and other components such as piping, wiring and/or ducting that are obscured by under-floor insulation are also excluded from this inspection. Note that the inspector does not determine if support posts, columns, beams, joists, studs, trusses, etc. are of adequate size, spanning or spacing.

The inspector does not guarantee or warrant that water will not accumulate in the basement in the future. Access to the basement during all seasons and during prolonged periods of all types of weather conditions (e.g. heavy rain, melting snow) would be needed to do so. The inspector does not determine the adequacy of basement floor or stairwell drains, or determine if such drains are clear or clogged.

Note that all basement areas should be checked periodically for water intrusion, plumbing leaks and pest activity.

The inspector does not guarantee or warrant that water will not accumulate in the basement in the future. Access to the basement during all seasons and during prolonged periods of all types of weather conditions (e.g. heavy rain, melting snow) would be needed to do so. The inspector does not determine the adequacy of basement floor or stairwell drains, or determine if such drains are clear or clogged.

Note that all basement areas should be checked periodically for water intrusion, plumbing leaks and pest activity.

Condition of exterior entry doors: Appeared serviceable

Exterior door material: Metal, Fiberglass or vinyl, Glass panel, Sliding glass

Condition of floor substructure above: Appeared serviceable

Pier or support post material: Bearing wall, Steel

Beam material: Steel

Floor structure above: Not determined (inaccessible or obscured)

Condition of insulation underneath floor above: Not determined (inaccessible or obscured)

Insulation material underneath floor above: Not determined (inaccessible or obscured)

7)

Photo 7-1 |

Photo 7-2 |

Photo 7-3 |

Roof

Limitations: The following items or areas are not included in this inspection: areas that could not be traversed or viewed clearly due to lack of access; solar roofing components. Any comments made regarding these items are made as a courtesy only. Note that the inspector does not provide an estimate of remaining life on the roof surface material, nor guarantee that leaks have not occurred in the roof surface, skylights or roof penetrations in the past. Regarding roof leaks, only active leaks, visible evidence of possible sources of leaks, and evidence of past leaks observed during the inspection are reported on as part of this inspection. The inspector does not guarantee or warrant that leaks will not occur in the future. Complete access to all roof and attic spaces during all seasons and during prolonged periods of all types of weather conditions (e.g. high wind and rain, melting snow) would be needed to do so. Occupants should monitor the condition of roofing materials in the future. For older roofs, recommend that a professional inspect the roof surface, flashings, appurtenances, etc. annually and maintain/repair as might be required. If needed, the roofer should enter attic space(s). Regarding the roof drainage system, unless the inspection was conducted during and after prolonged periods of heavy rain, the inspector was unable to determine if gutters, downspouts and extensions perform adequately or are leak-free.

Roof inspection method: Partially traversed

Condition of roof surface material: Appeared serviceable

Roof surface material: Asphalt or fiberglass composition shingles

Roof type: Hipped

Apparent number of layers of roof surface material: One

Condition of exposed flashings: Appeared serviceable

Condition of gutters, downspouts and extensions: Required repair, replacement and/or evaluation (see comments below)

8)

Photo 8-1 |

9)

Photo 9-1 |

10)

Photo 10-1 |

11) Roof Photos

Photo 11-1 |

Photo 11-2 |

Photo 11-3 |

Photo 11-4 |

Photo 11-5 |

Photo 11-6 |

Photo 11-7 |

Photo 11-8 |

Attic and Roof Structure

Limitations: The following items or areas are not included in this inspection: areas that could not be traversed or viewed clearly due to lack of access; areas and components obscured by insulation. Any comments made regarding these items are made as a courtesy only. The inspector does not determine the adequacy of the attic ventilation system. Complete access to all roof and attic spaces during all seasons and during prolonged periods of all types of weather conditions (e.g. high/low temperatures, high/low humidity, high wind and rain, melting snow) would be needed to do so. The inspector is not a licensed engineer and does not determine the adequacy of roof structure components such as trusses, rafters or ceiling beams, or their spacing or sizing.

Attic inspection method: Traversed

Condition of roof structure: Appeared serviceable

Roof structure type: Trusses

Ceiling structure: Trusses

Condition of insulation in attic (ceiling, skylight chase, etc.): Appeared serviceable

Ceiling insulation material: Spray polyurethane foam

Approximate attic insulation R value (may vary in areas): Not determined (inaccessible or obscured)

Vermiculite insulation present: None visible

Vapor retarder: None visible

12) Attic Photos

Photo 12-1 |

Photo 12-2 |

Photo 12-3 |

Photo 12-4 |

Photo 12-5 |

Photo 12-6 |

Photo 12-7 |

Photo 12-8 |

Garage or Carport

Limitations: The inspector does not determine the adequacy of firewall ratings. Requirements for ventilation in garages vary between municipalities.

Condition of door between garage and house: Appeared serviceable

Type of door between garage and house: Wood, Metal

Condition of garage vehicle door(s): Appeared serviceable

Type of garage vehicle door: Sectional

Number of vehicle doors: 2

Condition of automatic opener(s): Appeared serviceable

Mechanical auto-reverse operable (reverses when meeting reasonable resistance during closing): Yes

Condition of garage floor: Appeared serviceable

Condition of garage interior: Appeared serviceable

Garage ventilation: None visible

13) Garage Door Opener Photos

Photo 13-1 |

Photo 13-2 |

Photo 13-3 |

Photo 13-4 |

Photo 13-5 |

Photo 13-6 |

Photo 13-7 |

Electric

Limitations: The following items are not included in this inspection: generator systems, transfer switches, surge suppressors, inaccessible or concealed wiring; underground utilities and systems; low-voltage lighting or lighting on timers or sensors. Any comments made regarding these items are as a courtesy only. Note that the inspector does not determine the adequacy of grounding or bonding, if this system has an adequate capacity for the client's specific or anticipated needs, or if this system has any reserve capacity for additions or expansion. The inspector does not operate circuit breakers as part of the inspection, and does not install or change light bulbs. The inspector does not evaluate every wall switch or receptacle, but instead tests a representative number of them per various standards of practice. When furnishings, stored items or child-protective caps are present some receptacles are usually inaccessible and are not tested; these are excluded from this inspection. Receptacles that are not of standard 110 volt configuration, including 240-volt dryer receptacles, are not tested and are excluded. The functionality of, power source for and placement of smoke and carbon monoxide alarms is not determined as part of this inspection. Upon taking occupancy, proper operating and placement of smoke and carbon monoxide alarms should be verified and batteries should be changed. These devices have a limited lifespan and should be replaced every 10 years. The inspector attempts to locate and evaluate all main and sub-panels. However, panels are often concealed. If panels are found after the inspection, a qualified electrician should evaluate and repair if necessary. The inspector attempts to determine the overall electrical service size, but such estimates are not guaranteed because the overall capacity may be diminished by lesser-rated components in the system. Any repairs recommended should be made by a licensed electrician.

Electric service condition: Appeared serviceable

Primary service type: Underground

Number of service conductors: 3

Service voltage (volts): 120-240

Estimated service amperage: 600

Primary service overload protection type: Circuit breakers

Service entrance conductor material: Stranded copper

Main disconnect rating (amps): 600

System ground: Not determined, not readily apparent

Condition of main service panel: Appeared serviceable

Location of main service panel #A: Basement

Location of main service panel #B: Basement

Location of sub-panel #C: Basement

Location of main disconnect: Outside Disconnect

Condition of branch circuit wiring: Serviceable

Branch circuit wiring type: Non-metallic sheathed

Solid strand aluminum branch circuit wiring present: None visible

Ground fault circuit interrupter (GFCI) protection present: No

Arc fault circuit interrupter (AFCI) protection present: Yes

Smoke alarms installed: Yes, but not tested

14)

http://www.reporthost.com/?DBLTAP

Photo 14-1 |

Photo 14-2 |

Photo 14-3 |

Photo 14-4 |

15)

Photo 15-1 |

16)

Photo 16-1 |

17)

http://www.reporthost.com/?SMKALRM

http://www.reporthost.com/?COALRM

18)

Photo 18-1 |

Photo 18-2 |

Photo 18-3 |

19)

Photo 19-1 |

Photo 19-2 |

Photo 19-3 |

Photo 19-4 |

Photo 19-5 |

Photo 19-6 |

Photo 19-7 |

Photo 19-8 |

20) Electrical Equipment Photos

Photo 20-1 600 Amp Main Disconnect

|

Photo 20-2 |

Photo 20-3 |

Photo 20-4 |

Photo 20-5 |

Photo 20-6 |

Photo 20-7 |

Photo 20-8 |

21) The inspector was unable to determine the use of the light switch at the screened porch. Recommend verifying with the owner and have a electrician evaluate and repair if needed

Photo 21-1 |

Plumbing / Fuel Systems

Limitations: The following items are not included in this inspection: private/shared wells and related equipment; private sewage disposal systems; hot tubs or spas; main, side and lateral sewer lines; gray water systems; pressure boosting systems; trap primers; incinerating or composting toilets; fire suppression systems; water softeners, conditioners or filtering systems; plumbing components concealed within the foundation or building structure, or in inaccessible areas such as below tubs; underground utilities and systems; overflow drains for tubs and sinks; backflow prevention devices. Any comments made regarding these items are as a courtesy only. Note that the inspector does not operate water supply or shut-off valves due to the possibility of valves leaking or breaking when operated. The inspector does not test for lead in the water supply, the water pipes or solder, does not determine if plumbing and fuel lines are adequately sized, and does not determine the existence or condition of underground or above-ground fuel tanks.

Condition of service and main line: Appeared serviceable

Water service: Public

Water pressure (psi): 50

Location of main water shut-off: Basement

Condition of supply lines: Appeared serviceable

Supply pipe material: Copper

Condition of drain pipes: Appeared serviceable

Drain pipe material: Plastic

Condition of waste lines: Appeared serviceable

Waste pipe material: Plastic

Vent pipe condition: Appeared serviceable

Vent pipe material: Plastic

Sump pump installed: None visible

Sewage ejector pump installed: None visible

22)

http://www.reporthost.com/?WTRSFT

http://www.reporthost.com/?HRDWTR

Photo 22-1 |

23) Main Water Shut-off Valve, Pressure Reducing Valve, and Water Pressure Reading

Photo 23-1 Main Water Shut-off Valve

|

Photo 23-2 |

Photo 23-3 |

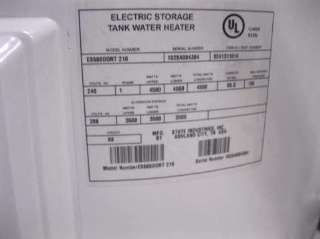

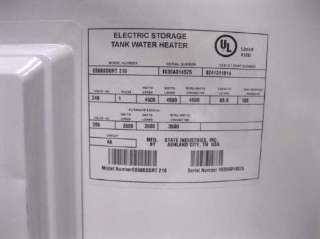

Water Heater

Limitations: Evaluation of and determining the adequacy or completeness of the following items are not included in this inspection: water recirculation pumps; solar water heating systems; Energy Smart or energy saver controls; catch pan drains. Any comments made regarding these items are as a courtesy only. Note that the inspector does not provide an estimate of remaining life on water heaters, does not determine if water heaters are appropriately sized, or perform any evaluations that require a pilot light to be lit or a shut-off valve to be operated.

Condition of water heater: Appeared serviceable

Type: Tank

Energy source: Electricity

Capacity (in gallons): (2) 80

Temperature-pressure relief valve installed: Yes

Location of water heater: Basement

Hot water temperature tested: Yes

Water temperature (degrees Fahrenheit): 114

24)

Photo 24-1 |

25) Water Heater Photos

Photo 25-1 |

Photo 25-2 |

Photo 25-3 |

Photo 25-4 |

Photo 25-5 Water Heater Shut-off Valve

|

Heating, Ventilation and Air Condition (HVAC)

Limitations: The following items are not included in this inspection: humidifiers, dehumidifiers, electronic air filters; solar, coal or wood-fired heat systems; thermostat or temperature control accuracy and timed functions; heating components concealed within the building structure or in inaccessible areas; underground utilities and systems; safety devices and controls (due to automatic operation). Any comments made regarding these items are as a courtesy only. Note that the inspector does not provide an estimate of remaining life on heating or cooling system components, does not determine if heating or cooling systems are appropriately sized, does not test coolant pressure, or perform any evaluations that require a pilot light to be lit, a shut-off valve to be operated, a circuit breaker to be turned "on" or a serviceman's or oil emergency switch to be operated. It is beyond the scope of this inspection to determine if furnace heat exchangers are intact and free of leaks. Condensation pans and drain lines may clog or leak at any time and should be monitored while in operation in the future. Where buildings contain furnishings or stored items, the inspector may not be able to verify that a heat source is present in all "liveable" rooms (e.g. bedrooms, kitchens and living/dining rooms).

General heating system type(s): Geothermal

General heating distribution type(s): Ducts and registers

Condition of forced air heating/(cooling) system: Appeared serviceable

Forced air heating system fuel type: Electric

Location of forced air furnace: Basement

Condition of furnace filters: Not determined (inaccessible, obscured or not found)

Location for forced air filter(s): None visible

Condition of forced air ducts and registers: Appeared serviceable

Condition of cooling system and/or heat pump: Appeared serviceable

Cooling system and/or heat pump fuel type: Electric

Type: Packaged unit

Condition of controls: Appeared serviceable

26)

Photo 26-1 |

Photo 26-2 |

27)

28) Geothermal Heat and Air System Photos

Photo 28-1 |

Photo 28-2 |

Photo 28-3 |

Photo 28-4 |

Photo 28-5 |

29) Electric Heater/Light/Exhaust Fan Combo

Photo 29-1 |

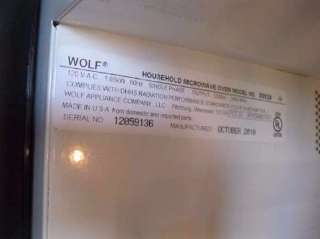

Kitchen

Limitations: The following items are not included in this inspection: household appliances such as stoves, ovens, cook tops, ranges, warming ovens, griddles, broilers, dishwashers, trash compactors, refrigerators, freezers, ice makers, hot water dispensers and water filters; appliance timers, clocks, cook functions, self and/or continuous cleaning operations, thermostat or temperature control accuracy, and lights. Any comments made regarding these items are as a courtesy only. Note that the inspector does not provide an estimate of the remaining life of appliances, and does not determine the adequacy of operation of appliances. The inspector does not note appliance manufacturers, models or serial numbers and does not determine if appliances are subject to recalls. Areas and components behind and obscured by appliances are inaccessible and excluded from this inspection.

Condition of counters: Appeared serviceable

Condition of cabinets: Required repair, replacement and/or evaluation (see comments below)

Condition of sinks and related plumbing: Required repair, replacement and/or evaluation (see comments below)

Condition of under-sink food disposal: Appeared serviceable

Condition of dishwasher: Appeared serviceable

Condition of range, cooktop or oven: Appeared serviceable

Range, cooktop or oven type: Electric

Type of ventilation: Hood or built into microwave over range or cooktop

Condition of refrigerator: Appeared serviceable

Condition of built-in microwave oven: Appeared serviceable

30)

Photo 30-1 |

Photo 30-2 |

Photo 30-3 |

Photo 30-4 |

Photo 30-5 |

31)

Photo 31-1 |

Photo 31-2 |

32) Kitchen Appliances Photos

Photo 32-1 |

Photo 32-2 |

Photo 32-3 |

Photo 32-4 |

Photo 32-5 |

Photo 32-6 |

Photo 32-7 |

Photo 32-8 |

Photo 32-9 |

Photo 32-10 |

Photo 32-11 |

Photo 32-12 |

Photo 32-13 |

Photo 32-14 |

Bathrooms, Laundry and Sinks

Limitations: The following items are not included in this inspection: overflow drains for tubs and sinks; heated towel racks, saunas, steam generators, clothes washers, clothes dryers. Any comments made regarding these items are as a courtesy only. Note that the inspector does not determine the adequacy of washing machine drain lines, washing machine catch pan drain lines, or clothes dryer exhaust ducts. The inspector does not operate water supply or shut-off valves for sinks, toilets, bidets, clothes washers, etc. due to the possibility of valves leaking or breaking when operated. The inspector does not determine if shower pans or tub and shower enclosures are water tight, or determine the completeness or operability of any gas piping to laundry appliances.

Location #A: Full bath, Master bath

Location #B: Half bath, first floor

Location #C: Full bath, basement

Location #D: Full bath, basement

Location #E: Half bath, basement

Condition of counters: Appeared serviceable

Condition of cabinets: Appeared serviceable

Condition of flooring: Appeared serviceable

Condition of sinks and related plumbing: Required repair, replacement and/or evaluation (see comments below)

Condition of toilets: Required repair, replacement and/or evaluation (see comments below)

Condition of bathtubs and related plumbing: Appeared serviceable

Condition of shower(s) and related plumbing: Required repair, replacement and/or evaluation (see comments below)

Condition of ventilation systems: Appeared serviceable

Bathroom and laundry ventilation type: Spot exhaust fans

Gas supply for laundry equipment present: No

240 volt receptacle for laundry equipment present: Yes

33)

Photo 33-1 |

34)

Photo 34-1 |

Photo 34-2 |

35)

Photo 35-1 |

Photo 35-2 |

36)

Photo 36-1 |

Photo 36-2 |

Interior, Doors and Windows

Limitations: The following items are not included in this inspection: security, intercom and sound systems; communications wiring; central vacuum systems; elevators and stair lifts; cosmetic deficiencies such as nail-pops, scuff marks, dents, dings, blemishes or issues due to normal wear and tear in wall, floor and ceiling surfaces and coverings, or in equipment; deficiencies relating to interior decorating; low voltage and gas lighting systems. Any comments made regarding these items are as a courtesy only. Note that the inspector does not evaluate any areas or items which require moving stored items, furnishings, debris, equipment, floor coverings, insulation or similar materials. The inspector does not test for asbestos, lead, radon, mold, hazardous waste, urea formaldehyde urethane, or any other toxic substance. Some items such as window, drawer, cabinet door or closet door operability are tested on a sampled basis. The client should be aware that paint may obscure wall and ceiling defects, floor coverings may obscure floor defects, and furnishings may obscure wall, floor and floor covering defects. If furnishings were present during the inspection, recommend a full evaluation of walls, floors and ceilings that were previously obscured when possible. Determining the cause and/or source of odors is not within the scope of this inspection.

Condition of exterior entry doors: Appeared serviceable

Exterior door material: Wood, Metal, Fiberglass or vinyl, Glass panel, Sliding glass

Condition of interior doors: Required repair, replacement and/or evaluation (see comments below)

Condition of windows and skylights: Appeared serviceable

Type(s) of windows: Vinyl, Multi-pane, Sliding, Casement, Fixed

Condition of walls and ceilings: Appeared serviceable

Wall type or covering: Drywall

Ceiling type or covering: Drywall, Tiles

Condition of flooring: Appeared serviceable

Condition of concrete slab floor(s): Appeared serviceable

Flooring type or covering: Wood or wood products, Tile

Condition of stairs, handrails and guardrails: Appeared serviceable

37)

Photo 37-1 |

Photo 37-2 |

Photo 37-3 |

Photo 37-4 |

Photo 37-5 |

Photo 37-6 |

Photo 37-7 |

Photo 37-8 |

38)

http://www.reporthost.com/?ECC

Photo 38-1 |

Photo 38-2 |

Photo 38-3 |

Photo 38-4 |

39)

Photo 39-1 |

Photo 39-2 |

Photo 39-3 |

Wood Destroying Organism Findings

Limitations: This report only includes findings from accessible and visible areas on the day of the inspection. In addition to the inaccessible areas documented in this report, examples of other inaccessible areas include: sub areas less than 18 inches in height; attic areas less than 5 feet in height, areas blocked by ducts, pipes or insulation; areas where locks or permanently attached covers prevent access; areas where insulation would be damaged if traversed; areas obscured by vegetation. All inaccessible areas are subject to infestation or damage from wood-destroying organisms. The inspector does not move furnishings, stored items, debris, floor or wall coverings, insulation, or other materials as part of the inspection, nor perform destructive testing. Wood-destroying organisms may infest, re-infest or become active at any time. No warranty is provided as part of this inspection.

Visible evidence of active wood-destroying insects: No

Visible evidence of past wood-destroying insects: Yes

Visible evidence of damage by wood-destroying insects: Yes

Location #A: Outside Exposed Beams

Location #B: Exterior Trim

40)

- Correct any conducive conditions for wood-destroying organisms mentioned in this report.

- Consult with the property owner about any history of infestation.

- Have a state-licensed pest control operator evaluate further and treat as necessary.

Photo 40-1 |

Photo 40-2 |

Photo 40-3 |

Photo 40-4 |

41)

- Correct any conducive conditions for wood-destroying organisms mentioned in this report.

- Consult with the property owner about any history of infestation.

- Have a state-licensed pest control operator evaluate further and treat as necessary.

Photo 41-1 Located on the side of the garage leading to the kitchen exterior door.

|

The home inspection report does not address environmental hazards including lead-based paint, radon, asbestos, cockroaches, termites, rodents, pesticides, treated lumber, fungus, Mercury, carbon monoxide, and other similar environmental hazards. That home inspection does not address subterranean systems or system components including sewage disposal, water supply, and fuel storage or delivery.