Inspector's email: saiedcoastalinspections@gmail.com

Phone: (949) 444-8033

Inspector's phone: (949) 294-4905

Inspector: Saied Pourzand

Property Inspection Report

| Client(s): | Home Buyer |

| Property address: | 1234 Perfect Street Ocean, CA |

| Inspection date: | Wednesday, November 23, 2016 |

This report published on Wednesday, November 30, 2016 9:45:56 AM PST

The following written report is prepared for the sole, confidential and exclusive use of the client(s) named above. It is designed to highlight major and significant defects observed on the day of the inspection, not minor or cosmetic ones (although these will be noted when observed as a courtesy). The report is intended as a general guide to help you evaluate the home. Read your entire Home Inspection Report before purchasing the property, paying close attention to all items noted on the report and to any exclusions and limitations listed. Any items noted that require further evaluation, any items not accessible or able to be located during the inspection and any items listed under the Visual Obstructions and Exclusions section should be investigated or evaluated before you purchase the home. I recommend that any needed repairs be made by a licensed, qualified contractor.

Your Home Inspection Report represents my good-faith opinions on the subjects listed within on the day of the inspection - no guarantee or warranty is either expressed or implied. Hidden or concealed defects are not included in this report. This report is not an insurance policy. Please be sure to read the entire report thoroughly and call promptly with any questions or concerns. This report shall supersede any written or verbal communication and comments made prior to providing the written report.

Best Wishes,

Saied Pourzand

California Architect

Licensed General Contractor

Certified Building Inspector

Inspector Introduction

Saied Pourzand is an InterNACHI Certified Inspector for existing and new residential & commercial buildings under ASHI or CREIA & ASTM standards; he holds a Bachelor degree in Architecture and Environmental Design from California Polytechnic State University San Luis Obispo with over 20 years of experience in the construction of educational, commercial and residential buildings; Licensed General Building Contractor (CSLB) specializing in residential constructions and renovations.

Saied has over 25 years cumulative experience in general building design and construction, educational projects (K12), residential and commercial property inspections. In addition, he is an active member of InterNACHI.

How to Read this Report

This report is organized by the property's functional areas. Within each functional area, descriptive information is listed first and is shown in bold type. Items of concern follow descriptive information.

Concerns are shown and sorted according to these types:| Safety | Poses a risk of injury or death | |

| Major Defect | Correction likely involves a significant expense | |

| Repair/Replace | Recommend repairing or replacing | |

| Repair/Maintain | Recommend repair and/or maintenance | |

| Future improvements | Recommended correction for future improvements | |

| Maintain | Recommend ongoing maintenance | |

| Evaluate | Recommend evaluation by a specialist | |

| Serviceable | Item or component is in serviceable condition | |

| Comment | For your information |

Click here for a glossary of building construction terms.Contact your inspector If there are terms that you do not understand, or visit the glossary of construction terms at http://www.reporthost.com/glossary.asp

Table of Contents

General informationExterior

Pool & Spa

Roof

Garage

Attic

Electric service

Water heater

Heating and cooling

Plumbing and laundry

Fireplaces and chimneys

Crawl space

Kitchen

Bathrooms

Interior rooms

General information

Report number: SampleReportSP

Inspector's name: Saied Pourzand

Structures inspected: Single Family Detached

Type of building: Single family

Age of building: 27

Property owner's name: Good Guys

Time started: 10:00 am

Time finished: 12:00 pm

Inspection Fee: $$$$$$

Payment method: Check

Present during inspection: Client(s), Realtor(s)

Occupied: No

Weather conditions: Clear

Temperature: Cool

Ground condition: Dry

Foundation type: Slab on grade, Crawlspace, Unfinished basement

The following items are excluded from this inspection: Security system, Irrigation system, Hot tub, Playground equipment, Low voltage outdoor lighting, Water filtration system, Water softener system, Built-in sound system, Intercom system, Fire suppression system

Note: This is a visual non invasive inspection that does not cover items that are not visible to the inspector at the time of inspection. This inspection is limited to the major components of the structure only. All components outside of the building envelope are excluded from this inspection unless noted otherwise. Please refer to the excluded items in this section of the report for an itemized list of items that are not covered in this inspection. Furthermore, this inspection is not meant to include cosmetic concerns, although they may be included in the report.

1)

Exterior

Foundation material: Poured in place concrete

Apparent wall structure: Wood frame

Wall covering: Stucco

Driveway material: Poured in place concrete, Asphalt, Natural stone tiles

Sidewalk material: Poured in place concrete, Paving stones

Exterior door material: Solid core wood, Glass panel

Safety Recommendations: Add a hand rail to all exterior staircases with three or more risers

2)

Photo 2-1 |

3)

Photo 3-1 |

Photo 3-2 |

Photo 3-3 |

4)

Photo 4-1 |

5)

Photo 5-1 |

6)

Photo 6-1 |

Photo 6-2 |

7)

Photo 7-1 |

8)

Photo 8-1 |

Photo 8-2 |

9)

Photo 9-1 |

Photo 9-2 |

Photo 9-3 |

10)

Photo 10-1 |

Photo 10-2 |

11) Other comments and concerns.

Photo 11-1 Broken vent at Crawl space access door

|

Photo 11-2 Corroded steel framing under entry staires

|

Photo 11-3 Grouts at main entry stairs are in need of maintenance, typical.

|

Photo 11-4 Grouts at main entry stairs are in need of maintenance, typical.

|

Photo 11-5 Grouts at main entry stairs are in need of maintenance, typical.

|

Photo 11-6 major crack at mid portion of stair wall and treads leading to back yard. Repair and maintain.

|

Photo 11-7 one or more Glass guardrail gaskets are in need of replacement or maintenance.

|

Photo 11-8 one or more Glass guardrail gaskets are in need of replacement or maintenance.

|

Photo 11-9 one or more Glass guardrail gaskets are in need of replacement or maintenance.

|

Photo 11-10 one or more Glass guardrail gaskets are in need of replacement or maintenance.

|

Photo 11-11 At one or more exterior wood finishes at main floor deck are in need of general maintenance.

|

Photo 11-12 Dented gutter in one side yard

|

Photo 11-13 At one or more exterior wood finishes at main floor deck are in need of general maintenance.

|

12) Metal vent system, wood framed with stucco covering. The Chimney system appear t be in serviceable condition.

Pool & Spa

13)

Photo 13-1 |

Photo 13-2 |

Photo 13-3 |

Roof

Roof inspection method: Viewed from ground, Viewed from windows

Roof type: Gable, Cross gable

Roof covering: Clay tile

Estimated age of roof: 27

Gutter & downspout material: Galvanized steel

Roof ventilation: Adequate

14)

Photo 14-1 |

15)

scope of this inspection. Even water stains on ceilings or on framing within attics does not necessarily confirm an active leak without some corroborative evidence, and such evidence can be deliberately concealed. We also can not predict the finish roofing materials remaining life expectancy, or guarantee that it will not leak.

We recommend that you ask the occupants about the roof conditions, and that you either include comprehensive roof coverage in your home insurance policy, or obtain a roof certification from an established local roofing company. We do not inspect attached accessories including by not limited to solar systems, antennas, and lightning arrestors, and these are exempt from this inspection.

Garage

Safety Recommendations: Update all garage outlets to GFCI outlets, Ground all open outlets in this garage

16)

http://www.cpsc.gov/cpscpub/pubs/523.html

http://www.ohdstl.com/safety.html

17)

18)

Photo 18-1 |

Photo 18-2 |

Photo 18-3 |

19)

Photo 19-1 |

Photo 19-2 |

Photo 19-3 |

20)

Attic

Inspection method: Viewed from hatch

Roof structure type: Rafters

Ceiling structure: Trusses, Ceiling beams

Insulation material: Fiberglass roll or batt

21)

22)

Photo 22-1 |

Photo 22-2 |

23)

Photo 23-1 |

Photo 23-2 |

24)

Photo 24-1 |

Photo 24-2 |

Photo 24-3 |

Photo 24-4 |

25)

Electric service

Primary service type: Underground

Primary service overload protection type: Circuit breakers

Service amperage (amps): 200

Service voltage (volts): 120/240

Location of main service panel: Side Yard

Location of main disconnect: Middle

Service entrance conductor material: Copper

System ground: Ground rod(s) in soil

Main disconnect rating (amps): 200

Safety Recommendations: Add arc fault circuit interrupter (AFCI) breakers in the main service panel for the bedroom circuits

Note: The inspection and evaluation of the electrical component of this structure if based on a visual inspection of these components only. The inspector can not verify or evaluate conditions that are not readily visible or located within the wall cavities of this structure.

26)

Replace non-matching breakers with breakers of the same brand as the panel manufacturer as necessary.

Photo 26-1 |

27)

28)

AFCI standards were introduced in the 1999 NEC (National Electrical Code) and are required in new dwelling construction and when installing new circuits in an existing dwelling.

As per the NEC, existing circuits need not be updated with AFCI circuit breakers in most circumstances. Some localities however, may have regulations that insist on certain upgrades under specific conditions. Always check with the local authority having jurisdiction to determine local requirements.

Photo 28-1 |

Photo 28-2 |

29)

Water heater

Type: Tank

Energy source: Natural gas

Capacity (in gallons): 50

Manufacturer: Bradford White

Note: Our inspection of major systems is limited to the normal operating functions of items listed. Independent evaluations including adequate sizing is not within the scope of this report. If such evaluation is required, we suggest contacting appropriate specialists.

30)

31)

Photo 31-1 |

Photo 31-2 |

Photo 31-3 |

Photo 31-4 |

Heating and cooling

Primary heating system energy source: Natural gas

Primary heat system type: Forced air

Primary A/C energy source: Electric

Primary Air conditioning type: Split system

Distribution system: Flexible ducts

Filter location: In return air duct below furnace

Note: Our inspection of major systems is limited to the normal operating functions of items listed. Independent evaluations including the adequacy/inadequacy of heating and cooling systems (such as adequate sizing of the units, cracked heat exchangers, air conditioning pressure tests, etc.) water flow (such as gallons per minute), electrical amperage/voltage adequacies are not within the scope of this report. If such detailed information is required, we suggest contacting appropriate specialists. Furthermore, these units will not be checked for recall by the inspection company.

32)

Photo 32-1 |

Photo 32-2 |

Photo 32-3 Condenser unit is equipped with adequate electrical shut off switches

|

33)

34)

35)

36)

Photo 36-1 |

37)

Photo 37-1 |

Photo 37-2 |

38)

Photo 38-1 |

39)

Photo 39-1 |

Photo 39-2 |

Photo 39-3 |

40)

Plumbing and laundry

Water Pressure: 50 psi

Location of main water meter: Sidewalk

Location of main fuel shut-off: Garage wall

Visible fuel storage systems: No

Water service: Public

Service pipe material: Copper

Supply pipe material: Copper

Vent pipe material: Plastic

Drain pipe material: Plastic

Waste pipe material: Plastic

Water pressure regulator valve: 50 psi

Recommendations: Install a pressure regulator valve to maintain a constant safe pressure inside the structure's plumbing lines.

41)

In addition, the client should be advised that either units could work in this layout with no needed modifications. However, the evaluation of the dryer's 240 volt electrical outlet is not within the scope of this inspection and the inspector can not verify current power or correct wiring of this outlet. Evaluate as necessary for proper functionality as necessary.

Photo 41-1 |

42)

43)

Seismic gas shut-off valves are designed to automatically shut off the supply of natural gas to a building during a major earthquake to prevent a fire or explosion from occurring due to the possible accumulation of gas in the building. Excess flow shut off valves are designed to automatically shut off when a significant gas leak or over pressure surge occurs downstream of the valve.

Currently the county of Orange does not require residential building to have this valve attached to their incoming gas lines. However other counties such as Los Angeles county require a seismic gas shut-off valve installed on designated buildings within their County.

Install one for a safe operations as needed.

Photo 43-1 |

44)

The main water supply piping and shut off valve appear to be in serviceable condition.

Photo 44-1 |

45)

46)

47)

48)

Fireplaces and chimneys

Fireplace type: Masonry with metal liner

Chimney type: Masonry

Fuel Type: Gas Burning only

49)

Photo 49-1 |

50)

Photo 50-1 |

51)

Photo 51-1 |

Photo 51-2 |

Crawl space

52)

Photo 52-1 |

Photo 52-2 |

Photo 52-3 |

Photo 52-4 |

53) Crawlspace was viewed from the access hatches and the basement. Areas beyond the inspectors visual range in the crawlspace are not covered in this report. Intent of this inspection is to get a sense of the house's structural make-up and stability. This inspection is not a complete crawlspace inspection and not all condition will be discovered during this physical inspection of this crawlspace area. Evaluate and conduct a crawlspace only inspection as necessary to determine a full study of this structure's make-up if needed.

54) No vapor barrier is installed. This is a conducive condition for wood destroying insects and organisms due to the likelihood of water evaporating into the structure from the soil. A qualified contractor should install a vapor barrier. Standard building practices require the following:

● The soil below the vapor barrier should be smooth and free from sharp objects. ● Seams should overlap a minimum of 12 inches. ● The vapor barrier should lap up onto the foundation side walls. Better building practices require that: ● Seams and protrusions should be sealed with a pressure sensitive tape. ● The vapor barrier should be caulked and attached tightly to the foundation side walls. For example, with furring strips and masonry nails.

Photo 54-1 |

Photo 54-2 |

Kitchen

Note: Inspection of kitchen components is limited to built-in gas or electric appliances and plumbing systems, if power is supplied. These items are tested under normal operating conditions. Extensive evaluations, such as calibration of timers, heat settings and temperature probes on cooking appliances are not within the scope of this report. Note: Due to the inaccessibility of the dishwasher components, we can do no more than operate under normal operating procedures. Dishwashers can fail at any time due to their complexity. Our review is to determine if the system is free of leaks and excessive corrosion. Shutoff valves and angle stops under kitchen or bathroom sinks and toilets are not turned or tested during the inspection due to the possibility of leaking. We suggest all shutoff valves or angle stops be turned regularly to ensure free movement in case of emergency.

Safety Recommendations: Upgrade kitchen counter outlets to GFI outlets within 6' of the sink

55)

Photo 55-1 |

56)

Photo 56-1 |

57)

Photo 57-1 |

Photo 57-2 |

58)

Photo 58-1 |

Photo 58-2 |

Photo 58-3 |

Photo 58-4 |

Bathrooms

59)

Photo 59-1 |

Photo 59-2 |

60)

Photo 60-1 |

61)

Photo 61-1 |

62)

Photo 62-1 |

Photo 62-2 |

Photo 62-3 |

Photo 62-4 |

Photo 62-5 |

Interior rooms

63)

Grounding type receptacles began being required in residential structures during the 1960s. Based on the age of this structure and the presence of 2-pronged receptacles in some areas of this structure, an acceptable repair may be to simply replace the ungrounded 3-pronged receptacles with 2-pronged receptacles. However the following appliances require grounding type receptacles:

- Computer hardware

- Refrigerators

- Freezers

- Air conditioners

- Clothes washers

- Clothes dryers

- Dishwashers

- Kitchen food waste disposers

- Information technology equipment

- Sump pumps

- Electrical aquarium equipment

- Hand-held motor-operated tools

- Stationary and fixed motor-operated tools

- Light industrial motor-operated tools

- Hedge clippers

- Lawn mowers

This list is not exhaustive. Grounded circuits and receptacles should be installed in locations where such appliances will be used.

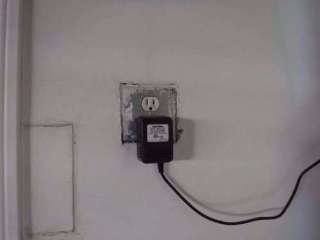

Photo 63-1 |

Photo 63-2 |

Photo 63-3 |

64)

Proper placement of a carbon monoxide (CO) detector is important. If you are installing only one carbon monoxide detector, the Consumer Product Safety Commission (CPSC) recommends it be located near the sleeping area, where it can wake you if you are asleep. Additional detectors on every level and in every bedroom of a home provides extra protection against carbon monoxide poisoning.

Homeowners should remember not to install carbon monoxide detectors directly above or beside fuel-burning appliances, as appliances may emit a small amount of carbon monoxide upon start-up. A detector should not be placed within fifteen feet of heating or cooking appliances or in or near very humid areas such as bathrooms.

65)

Photo 65-1 |

Photo 65-2 |

66)

http://www.cpsc.gov/cpscpub/pubs/5077.html

67)

Photo 67-1 |

Photo 67-2 |

Photo 67-3 |

68)

Photo 68-1 |

Photo 68-2 |

69)

70)

Photo 70-1 noted open ground outlet without cover plate in garage. remove, and replace.

|

Photo 70-2 broken window gasket

|

Photo 70-3 repair unfinished wall portion

|

Photo 70-4 repair unfinished wall portion.

|

71)

72)

This inspection meets or exceeds the Standards of Practice for the InterNational Association of Certified Home Inspectors (NACHI). It is intended as a general guide to help you make an evaluation as to the overall condition of the home. It is not intended to place a value on the home nor make any representation as to the advisability of purchase. It is not a guarantee or warranty. It is not an insurance policy.

The report reflects the opinion of the inspector(s), based upon visual impressions of conditions that existed at the time of inspection. The inspection is not intended to be technically exhaustive or to imply that every component in the home was inspected. No disassembly of equipment, opening of walls, moving of furniture or stored items was performed or is allowed by state requirements. All components which were concealed or obscured from observation at the time of inspection (including those concealed by clutter and stored items) are necessarily excluded from the report. Unless noted otherwise the house exterior was inspected from the ground. Only a representative sampling of parts and components (windows, electrical outlets, roof shingles, exterior wall trim and cladding, etc.) were examined and are within the scope of this inspection. Unless noted otherwise roofs and roofing materials are inspected from the ground with binoculars, from the roof edge when possible or from windows overlooking the roof.

Environmental hazards are not within the scope of the inspection and are excluded from the report. Any hazards noticed while performing the building inspection will be listed in the "Possible Environmental Hazards" section for your convenience so you can have them further investigated by an expert. These hazards include but are not limited to radon gas, carbon monoxide, lead and lead paint, buried storage tanks, asbestos, vermiculite, urea formaldehyde, and mold. Also excluded from the report are heating system heat exchangers, pools, hot tubs, spas, fountains, exterior lighting, water wells, zoning ordinances, intercoms, playground equipment, sports courts, elevators, outbuildings, septic tanks and sewage systems, water treatment equipment, security systems, sprinkler systems (both fire and lawn), bridges (over culverts, streams, ponds, etc.), generators, greenhouses, and central vacuum systems. Condo common areas are excluded. This is not an inspection for insects (including wood destroying), rodents birds, or other infestations. Reinspections or additional testing is not included and will incur an additional fee if needed. No warranty or guaranty of the home or components is implied by Coastal Home Inspections.

This inspection report is not a compliance inspection for any government codes or regulations, nor as a property or land survey. The types of water supply (public supply or private well) and waste disposal (public sewer or private septic system) cannot be accurately determined by a home inspection and were not part of your home examination. I recommend you check with your local City or other source of building records / permits to verify your type of system before purchase.